INDUSTRIAL BOILERS FOR BOTTLES

4-12 rows with capacity up to 30,000 pcs / hour.

Production of rolls with a weight of 28-300 grams

Production of rolls with a weight of 28-300 grams

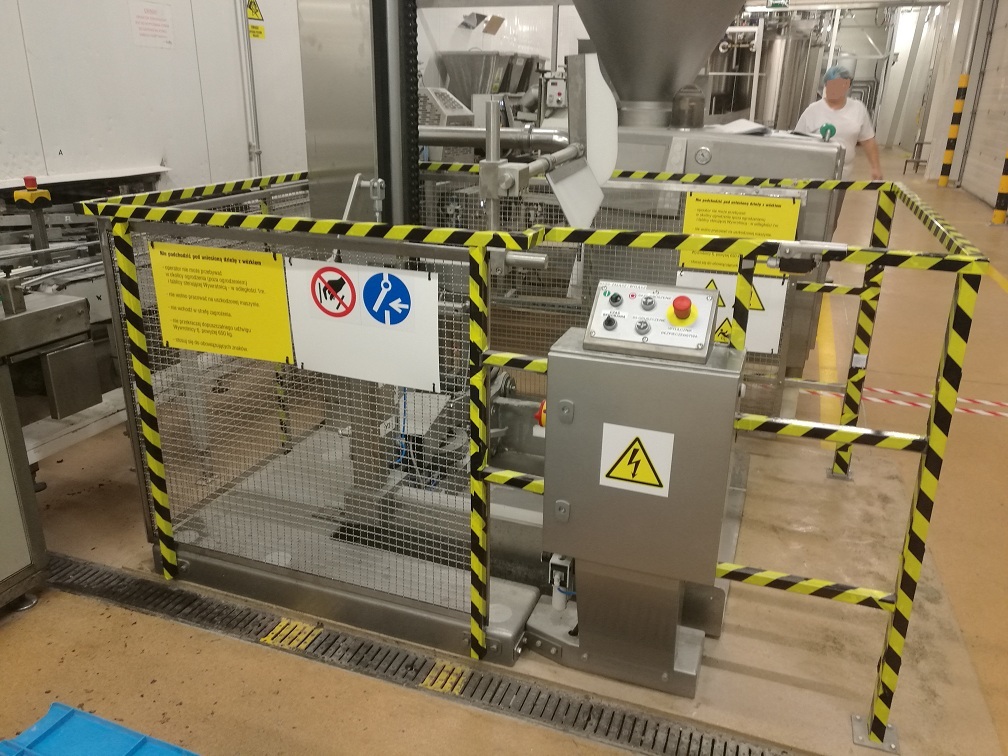

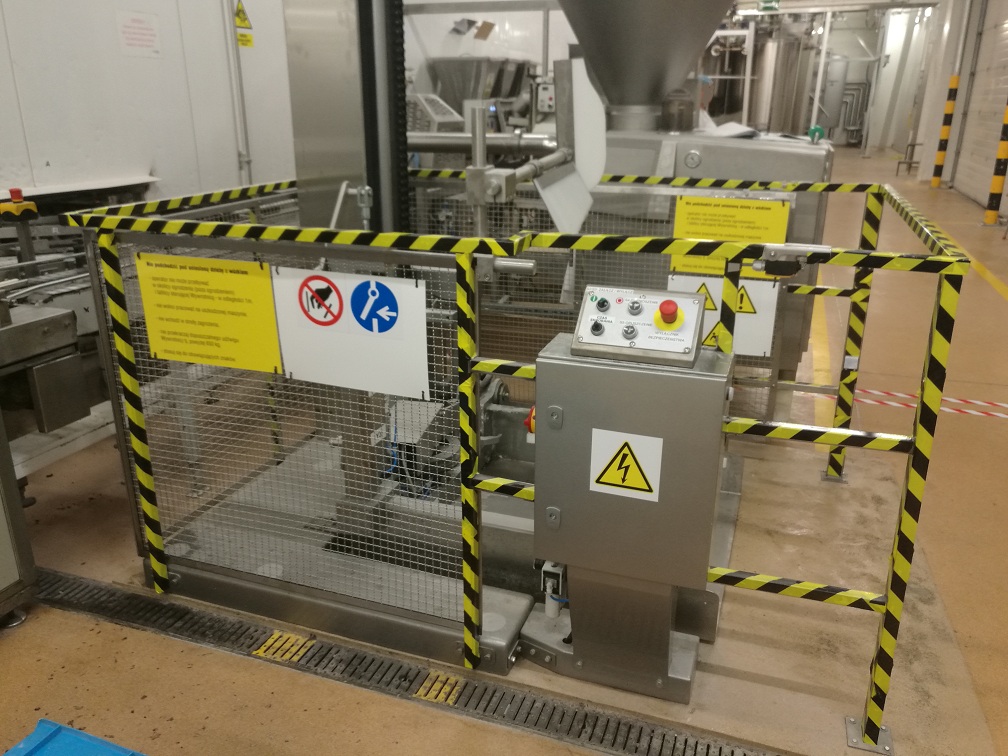

TIPPLER FIT TO KETTLE WP 120 UC

MODELS AND COMBINATIONS

- 50mm – 65mm dough chamber option to achieve 28 grams – 350 grams dough portioning.

- Standard or Lowered Moulding gearbox to ensure dough drop accuracy.

- Standard or Elevated flour dusters to help with flour feed to moulding drums.

- Single or Multiple discharge Spreader belts for aligning and spacing product rows.

- Rotary Head and Ram Assembly lubrication to help dough release and vacuum seal.

- Single or Twin Air Knifes to help the dough release from Moulding drums.

SPEED

| Speed | 12 row max | 9 row max | 6 row max | 4 row max |

| 28 – 100 grams = 3000 pieces per hour per Piston | 36000 p/h | – | – | – |

| 100 – 160 grams = 2750 pieces per hour per Piston | – | 24750 p/h | – | – |

| 160 – 230 grams = 2500 pieces per hour per Piston | – | – | 15000 p/h | – |

| 230 – 350 grams = 2000 pieces per hour per piston | – | – | – | 8000 p/h |

WEIGHT RANGE

The volumetric dough portioning system ranges from 28 Grams to 350 Grams.

NOTE: Volume to weight range may vary slightly dependent of percentage of water in recipe.

ACCURACY

28 – 100 grams = +/- 1-2 grams per dough piece

100 – 160 grams = +/- 2 grams per dough piece

160 – 230 grams = +/- 2-3 grams per dough piece

230 – 350 grams = +/- 3 grams per dough piece

APPLICATION

Our divider rounders can be install to new or existing production lines:

- Pizzas

- Pitas

- Tortilla

- Naan

- Subs

- Rolls

- Bagels

Our divider rounders can handle most doughs with a water content up to 60% – 70% dependent on the protein levels and flour quality.